DO

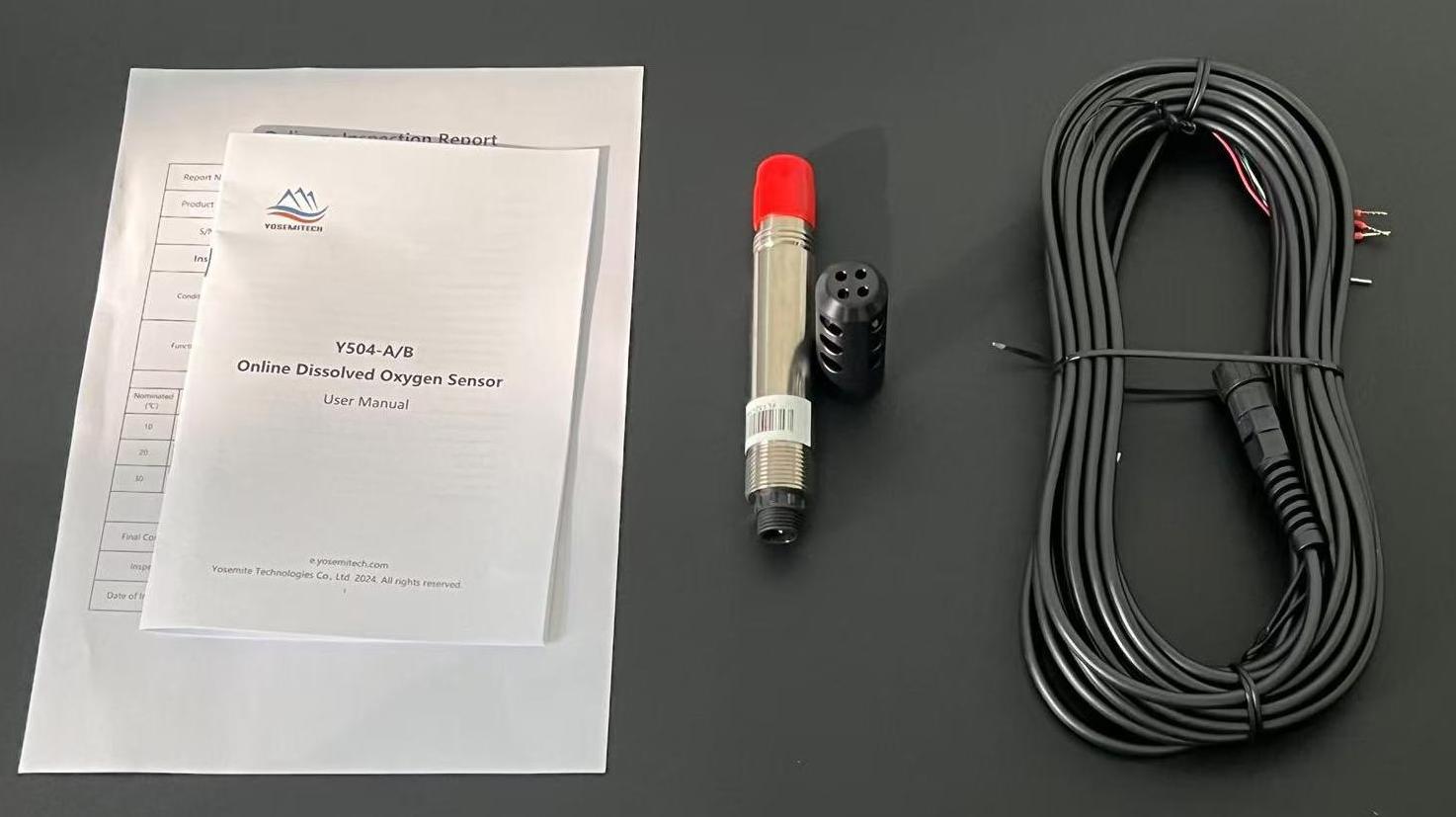

Y504-A Online Optical Dissolved Oxygen Sensor

- Product Model:Y504-A

- Time: 2019-09-18 03:59:01

- Product description:Professional Y504-A optical dissolved oxygen sensor featuring advanced fluorescence technology, digital RS485 output, and maintenance-free operation. Ideal for wastewater, aquaculture, and industrial applications.

Yosomitech Y504-A Optical Dissolved Oxygen Sensor is an online device for measuring dissolved oxygen in water. Our Optical Dissolved Oxygen Probe adopts oxygen dynamic luminescence quenching technique; when blue light excites sensor film it emits red light which can then be measured to calculate DO concentration. When blue excitation meets red emission the phase difference between them can be calculated and then used to calculate DO concentration.

Y504-A Optical Do Probe doesn't consume oxygen, has no flow rate limit, doesn't require electrolyte, is free of frequent maintenance and calibration, isn't affected by hydrogen sulfide, and has excellent accuracy and stability.

It's widely used in Municipal wastewater treatment, Industrial process control, Environmental monitoring, Aquaculture systems, Surface water quality assessment, Research laboratories, Brewing and fermentation.

Digital Sensor, RS-485 Output, MODBUS Protocol.

Fluorescence Measurement Method, No Calibration Required, No Membranes to Replace, Reducing Maintenance.

No Oxygen Consumption, Strong Anti-interference.

Low drift, Fast Response, More Accurate, Online Real-time Measuring.

Built-in Temperature Sensor, Automatic Temperature Compensation.

Widely Used in Environmental, Groundwater Monitoring, Aquaculture, Marine Research, Wastewater Treatment and etc..

Name | Dissolved oxygen sensor |

Model | Y504-A |

Range | 0-20mg/L or 0-200 % saturation |

Response Time | 10 sec |

Housing IP Rating | IP68 |

Maximum water depth | 60m |

Accuracy | ±1% |

Drift | <1%per year |

Temperature range | 0 ~ 50℃ |

Temperature accuracy | ±0.2℃ |

Sensor Interface | Supports RS-485, MODBUS protocol |

Power Requirements | DC 9-24V, current <50mA |

Construction | 3/4 inch NPT |

Temperature Sensor | NTC |

Sensor size | Φ26mm*187mm(with protective cover) |

Probe cable length | 10m (default), customizable |

Calibration | One point or two points calibration |

Fluorescent cap life | 1 Year(at normal use) |

Sensor housing material | Titanium alloy |

Contact Yosemitech

CATEGORIES

CONTACT US

Yosemitech Technologies Co., Ltd

+86 19984844080

+86 19984844080

sales@yosemitech.com

sales@yosemitech.com

Bldg,25,CECEP Industrial Park, No. 18 Dongchang Rd. Suzhou Industrial Park, Jiangsu Province,China 215126, China

Bldg,25,CECEP Industrial Park, No. 18 Dongchang Rd. Suzhou Industrial Park, Jiangsu Province,China 215126, China