0512-87663997

sales@yosemitech.com

Writer: admin Time:2023-08-08 15:08:25 Browse:244℃

Required equipments and raw materials

required equipments: two 250mL beakers, one set of gloves

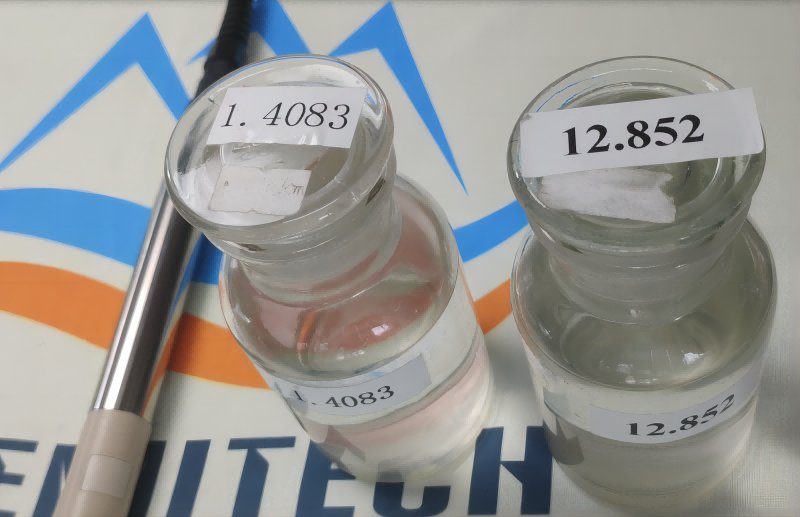

raw materials: 1.4083mS/cm conductivity standard solution, 12.852mS/cm conductivity standard solution

Calibration steps

There are two methods of user calibration for the conductivity sensor: one-point calibration and two-points calibration.

One-point calibration step (change the K value)

Step 1: put an appropriate amount of 1.4083mS/cm conductivity standard solution into a 250mL beaker, put the sensor into the beaker, shake the sensor gently to remove air bubbles from the front of the sensor;

Step 2: insert the RS485 to USB connector connected to the sensor cable into the computer, open the SmartPC software on the computer, click “Language” and select “Chinese”, drop down “Port” and select the corresponding COM port, and then click “Connect”, after connecting the sensor successfully, click “Measure”, and then click “Start” to get the real-time measurement of the conductivity, TDS and temperature;

Step 3: click “Stop” to end the data measuring, then click “Calibrate”, and click “Get” under the “Manual Calibration” interface to get the initial K and B values of the sensor. Under the “Automatic Calibration” interface, change the “Single/First Point Calibration Value” to 1.4083, click “1 point” to do one-point calibration, wait for the values in the pop-up window to stabilize, and click “OK” to complete the calibration. Click “Get” to check whether the K value is written correctly;

Step 4: click “Start” under the “CT” interface to get the real-time measurement of the conductivity, TDS and temperature, check that the conductivity is close to 1.41mS/cm to verify that the one-point calibration is successful.

Two-points calibration step (change the K and B values)

Step 1: put an appropriate amount of 1.4083mS/cm conductivity standard solution into a 250mL beaker, put an appropriate amount of 12.852mS/cm conductivity standard solution into another 250mL beaker;

Step 2: put the sensor into the beaker containing 1.4083mS/cm conductivity standard solution, shake the sensor gently to remove air bubbles from the front of the sensor;

Step 3: insert the RS485 to USB connector connected to the sensor cable into the computer, open the SmartPC software on the computer, click “Language” and select “Chinese”, drop down “Port” and select the corresponding COM port, and then click “Connect”, after connecting the sensor successfully, click “Measure”, and then click “Start” to get the real-time measurement of the conductivity, TDS and temperature;

Step 4: click “Stop” to end the data measuring, then click “Calibrate”, and click “Get” under the “Manual Calibration” interface to get the initial K and B values of the sensor. Under the “Automatic Calibration” interface, change the “Single/First Point Calibration Value” to 1.4083, change the “Second Point Calibration Value” to 12.852, click “2 points” to do two-points calibration, wait for the values in the pop-up window to stabilize, and click “OK”. Then clean the sensor with distilled water or deionized water, wipe it dry and put it into the beaker containing 12.852mS/cm conductivity standard solution, shake the sensor gently to remove air bubbles from the front of the sensor, wait for the values in the pop-up window to stabilize, and click “OK” to complete the calibration. Click “Get” to check whether the K and B values are written correctly;

Step 5: click “Start” under the “CT” interface to get the real-time measurement of the conductivity, TDS and temperature, check that the conductivity is close to 12.85mS/cm, then clean the sensor with distilled water or deionized water, wipe it dry and put it into the beaker containing 1.4083mS/cm conductivity standard solution, shake the sensor gently to remove air bubbles from the front of the sensor, get the real-time measurement of the conductivity, TDS and temperature, check that the conductivity is close to 1.41mS/cm to verify that the two-points calibration is successful.

Yosemitech Technologies Co., Ltd

Email: sales@yosemitech.com

Add: Bldg,25,CECEP Industrial Park, No. 18 Dongchang Rd. Suzhou Industrial Park, Jiangsu Province,China 215126, China